First safety function: a 3D, variable aperture virtual barrier with up to four different detection fields, providing a secure signal to control machinery.

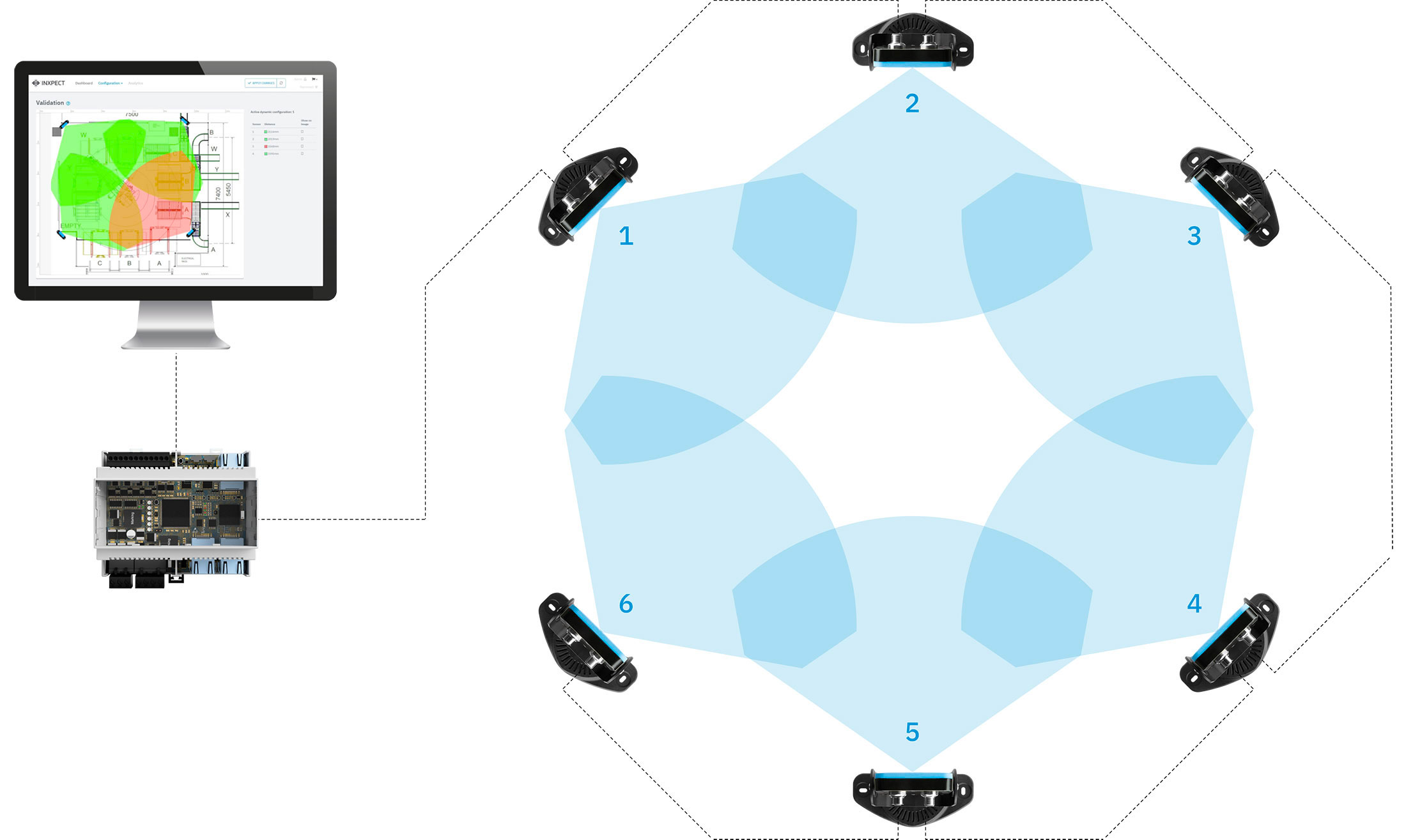

Second safety function: safe presence sensing to prevent machinery from starting as long as operators are in dangerous areas.

The field of view is dynamically selectable both in range and in horizontal aperture (from 10 to 100 deg. in 10 deg. increments): perfect for moving applications.

The Ethernet safety fieldbus simplifies the integration of the SBV System Bus with any machinery or robot, and allows it to exchange complex information, such as real time operator position.

IP connectivity allows configuration and management of the system from any point in the network.

The system can be configured to temporarily deactivate some sensors when they are not required to detect motion in the area, allowing operators to access parts of the working area.

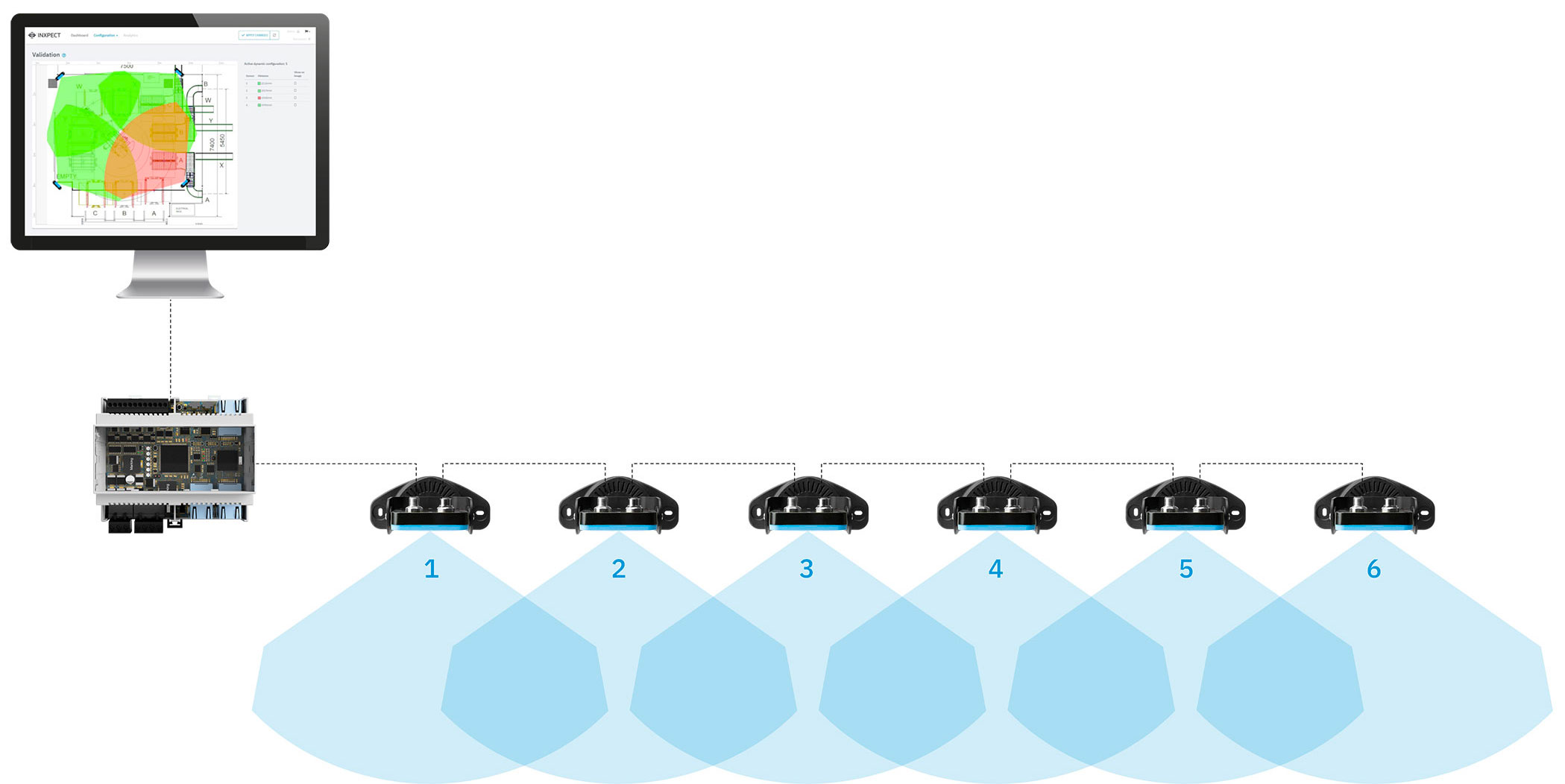

One control unit, from one to six sensors: small to large, simple to complex, a solution for every requirement.

| SBV SYSTEM BUS | |

|---|---|

| Detection method | Inxpect motion detection algorithm based on FMCW radar |

| Frequency |

Working band: 60 GHz Transmission power: ≤ 13 dBm - Modulation: FMCW |

| Detection range |

From 0 to 5 m (0 to 16.4 ft), depending on the installation conditions (Long range version available by mid 2021) |

|

Sensing field and installation range |

FOV: 10-100° Horiz. (in 10 deg. increments) 20° Vert., Range: 0.5 to 5 m (1,6 to 16.4 ft) |

| Power consumption | 21,8 W (no OSSD), for a fully loaded system with six sensors |

| Operating Temperature | From -30 to +60 °C (-22 to +140 °F) |

| Storage Temperature | From -30 to +60 °C (-22 to +140 °F) |

|

Communication protocol (sensors-controller) |

CAN complies with standard EN 50325-5 |

| Warranty period | 36 months from the date of purchase of the product |

| SBV-01 SENSOR | |

|---|---|

| Connectors | Two 5-pin M12 connectors (1 male and 1 female) |

| CAN bus termination resistance | 120 Ω (not supplied, to be installed with termination connector) |

| Power supply | 12 V dc ± 20%, through controller |

| Degree of protection | IP67 |

| Material | Sensor: PA66 (front) + Aluminum (back) | Bracket: PA66 and glass fiber (GF) |

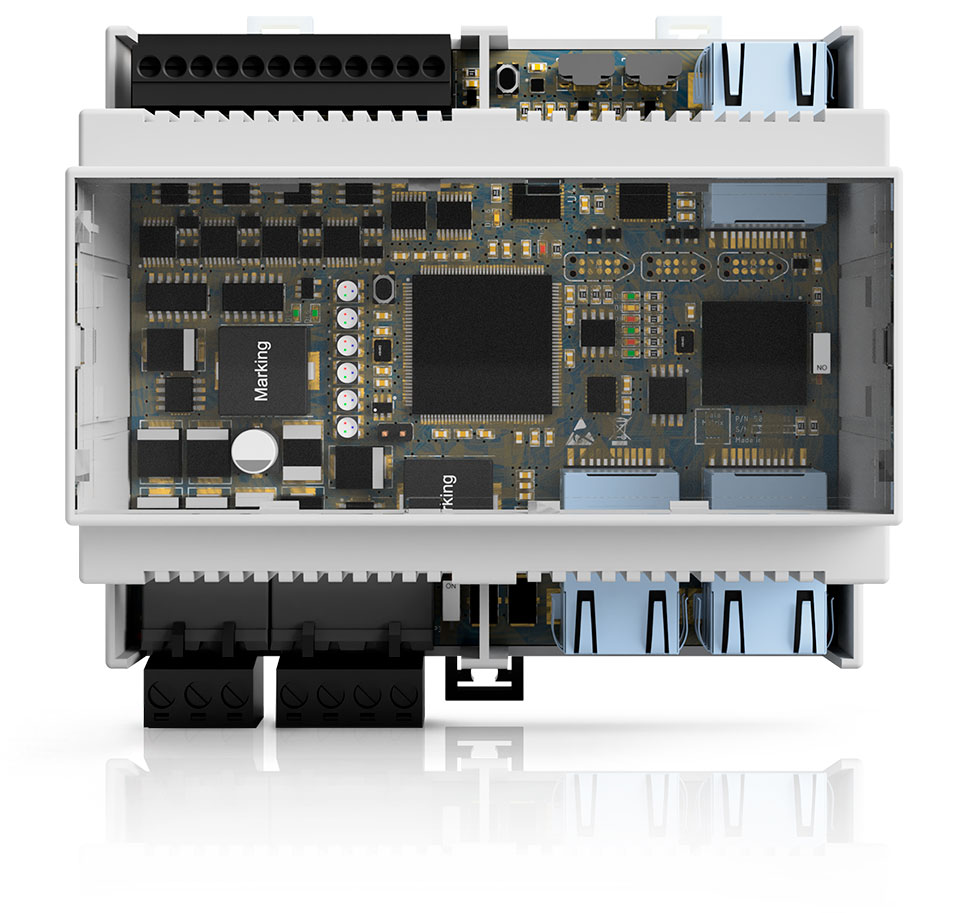

| ISC-B01 CONTROL UNIT | |

|---|---|

| Outputs |

4 Outputs Signal Switching Devices (OSSDs) 2 dual channel safety outputs |

| Safety outputs |

High-side outputs (with extended protection function) Max voltage 30V dc | Max current: 0,4A | Max power: 12W |

| Inputs |

2 dual channel TYPE3 digital inputs with common GND |

| Power supply | 24 Vdc (20–28 Vdc) Max current: 1A (no OSSD) |

| Power consumption | 5 W (no OSSD), stand alone with no sensors connected |

| Assembly | DIN guide |

| Degree of protection | IP20 |

| Terminals | Removable screw terminals. Section: 1 mm2 | Max Current: 4A with 1 mm2 cables |

Inxpect radar systems adapt to many different usage situations in a wide range of working environments. Below are some of the most common usage scenarios, where radar technology has significantly increased safety levels in industrial environments.